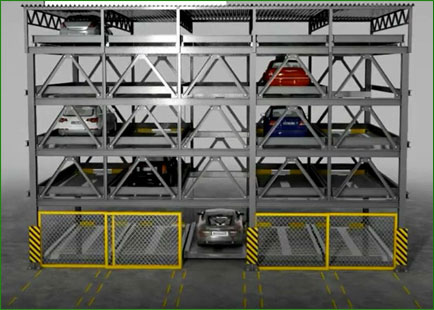

LIFT & SLIDE PARKING SYSTEM

LIFT AND SLIDE Parking System often nicknamed the puzzle system or robotic system. This system can have more than two levels of parking. It’s design has a structure that enables use of all parking entrances and exits on ground level. The parking pallet moves left, right, upward, and downward and has always a minimum of one empty slot for movement. Car parker can have multiple levels above, pit style below, or a combination of both. Up to 5 to 28 Cars can be accommodated within the space normally taken up by 3 cars.

HOW IT WORKS?The ground level parking trays move left and right. This allows the top and bottom rows to be stored and retrieved.

This system is suitable for indoor or outdoor installation in commercial, office, and residential applications. Operation is very efficient and timely, allowing for a vehicle to be retrieved in 60 seconds or less. Vehicle retrieval is performed via a PLC touch screen control that provides a user friendly one-touch operation.

The system can be ordered from a minimum of 2 wide (housing 5 vehicles) up to many wide (please discuss your needs with a sales agent). Optional equipment that can be ordered includes special payment processing kiosks, vehicle detection sensors, light and voice alerts, driving platform catwalks, and a liquid drainage system.

FEATURES

1. It is controlled with PLC system, IC card and buttons

2. It is mostly installed outdoors but can be installed under canopy as well.

3. Driven by motors and chain system.

4. Multiple security detection devices are configured in order to ensure safe and reliable operation.

5. Anti-fall device

6. Alarm device for preventing people or car from entering when the machinery is running.

7. Alarm device for prevention of exceeding height and length of cars

8. Low-voltage, lack-phase, over-current and overload protection device

9. Power-off self-locking protection device

10. Emergency stop button device.

TECHNICAL DETAILS

SL.NO

DESCRIPTION

SPECIFICATIONS

1

Model

LSM

2

Mode of Operation

Manual Control Keys

3

Drive Motor

5 KW

4

Mode of Drive

Roller Chain

5

Control System

Software & PLC Total Control shall be of Mitsubishi, Japan.

Motors & Gear system shall be of SEW, Germany.

Other Electronic Controls shall be of HMM, Turkey.

6

Certification

ISO 9001 : 2015; CE/ TSE/TUV

7

Control

PLC mode (default), Button mode (default),